Multi-Point Fuel Injection - A Revolution in Automotive Fuel Systems

Key Highlights:

- Multi-Point Fuel Injection system is often considered a pivotal milestone in automotive engineering.

- Stricter emission norms were the most influential factor in introducing MPFI technology.

- GDI systems are gradually taking over the industry, especially in turbo petrol powertrains.

What is an MPFI System?

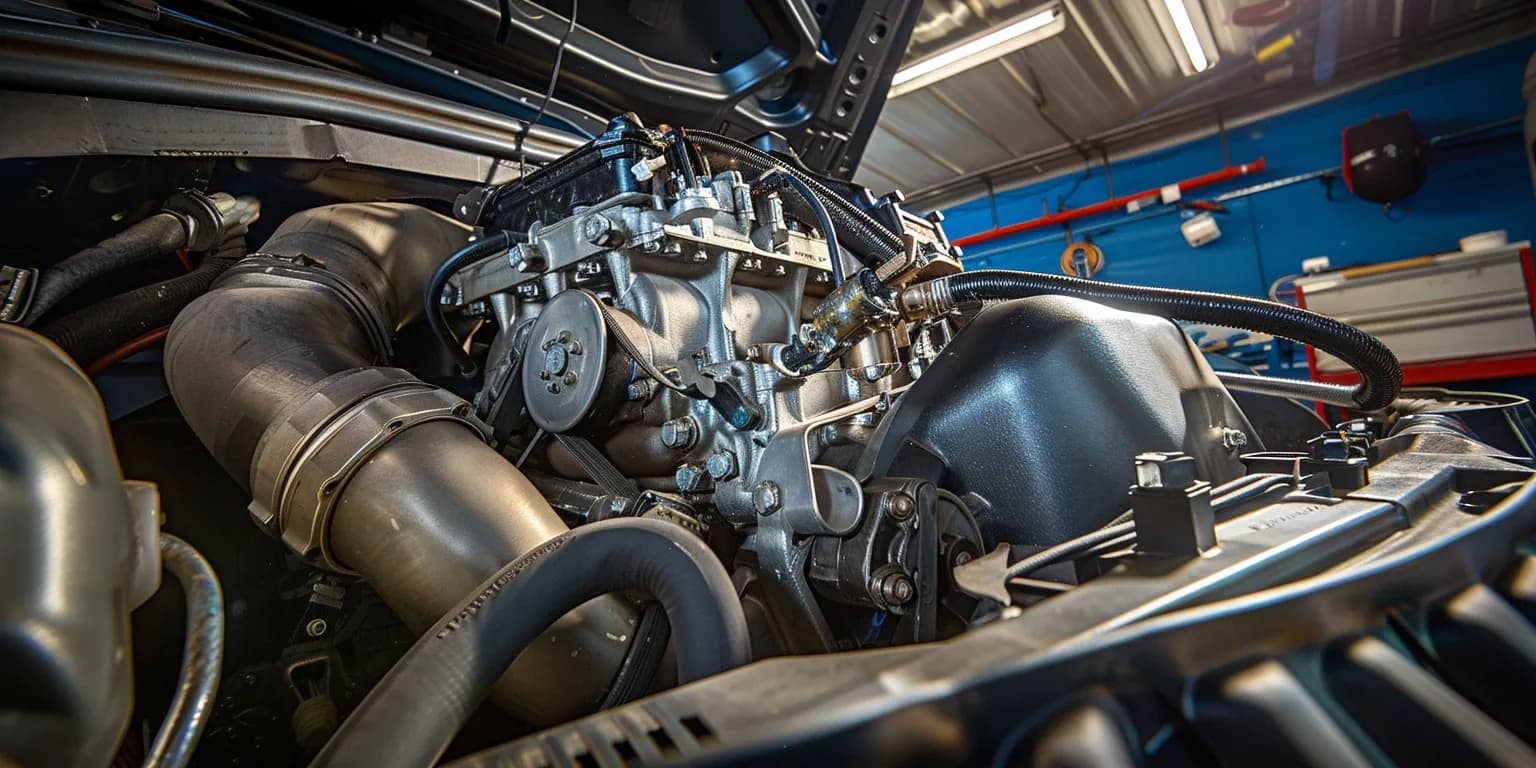

MPFI refers to Multi-Point Fuel Injection, a fuel delivery method used in internal combustion engines, especially those powered by petrol. In this system, every cylinder in the engine is equipped with its own fuel injector. Each injector delivers an exact amount of fuel into the intake port situated just ahead of the intake valve. Within this port, the fuel blends with air before entering the combustion chamber as the valve opens. This process guarantees that the air-fuel mixture reaching each cylinder remains uniform and accurately controlled.

Compared to older systems such as single-point injection or carburettors, MPFI delivers superior fuel atomisation. Fuel is broken down into finer particles before it mixes with air, which helps it burn more efficiently during combustion. This improved combustion enhances engine performance while also reducing emissions and increasing fuel efficiency.

How Does MPFI Work?

The MPFI system’s main components include the Electronic Control Unit or ECU, fuel injectors, fuel pump, fuel rail, multiple sensors and the air intake system. The ECU constantly gathers information from several sensors (throttle position, mass airflow, engine temperature and oxygen). Using the data, the ECU calculates the precise amount of fuel required and instructs each injector to release it at the appropriate moment.

Fuel is pumped into the fuel rail, which serves as a supply channel for the injectors. Each injector is managed electronically and sprays fuel into its designated intake port in the form of a fine mist. The spray pattern and timing are vital, and hence, the ECU continuously adjusts them based on engine load, speed and various other conditions. This process ensures that every cylinder receives a well-balanced mix of air and fuel, which is then ignited by the spark plug to generate power.

Benefits of MPFI Over Traditional Carburettors

MPFI systems introduced several advancements compared to older carburettor setups. While carburettors depend on vacuum pressure and mechanical components to supply fuel, this method often leads to uneven fuel distribution among the cylinders. In comparison, MPFI systems utilise electronic controls to manage fuel injection with greater precision.

A key advantage of the MPFI system is its improved fuel efficiency. Since fuel is delivered precisely to each cylinder, wastage is kept to a minimum. This also results in cleaner emissions, allowing vehicles to meet strict emission regulations.

MPFI engines typically deliver smoother and more responsive acceleration. They are also easier to start in cold weather and need less maintenance because they are not affected by problems such as fuel flooding or clogging, which are often seen in carburettor-based systems.

Another significant advantage of MPFI systems is their ability to support more precise engine tuning. This allows for accurate adjustment of parameters like the air-fuel ratio and ignition timing, leading to improved overall engine performance.

Types of MPFI Systems

MPFI systems in vehicles are generally of two main types: sequential and batch fire. In the former setup, each injector operates individually, timed precisely with the engine's firing order. This results in more accurate fuel delivery, which enhances both efficiency and performance.

In the latter, multiple injectors are actuated at once, without considering the position of each cylinder in the firing sequence. Although this approach is simpler and more cost-effective, it does not match the efficiency of the sequential system. Because of its better control and overall advantages, the sequential MPFI system is commonly found in modern cars.

Limitations of MPFI

A major limitation is that it delivers fuel into the intake port instead of directly into the combustion chamber. This can lead to minor fuel losses, as some of the fuel may settle on the intake walls before it is burned.

Another drawback is the complexity. MPFI includes a greater number of components and electronic controls compared to the more basic carburettor systems, which can make both repairs and diagnostics complicated and costlier. Furthermore, while MPFI is generally efficient, it does not match the precision and performance levels provided by some of the more advanced fuel injection technologies available today, such as GDI.

Alternative Technologies

As the focus on fuel efficiency, performance and lower emissions continues to grow, manufacturers have introduced newer alternatives to the MPFI system. Among the most notable of these is Gasoline Direct Injection, or simply, GDI.

In GDI systems, fuel is delivered straight into the combustion chamber instead of the intake port. This method enables more accurate control of the air-fuel mixture, particularly when engine loads change. Since the fuel is injected at high pressure directly into the chamber, it blends more thoroughly with air, leading to more efficient combustion.

Compared to MPFI engines of similar size, GDI engines are capable of producing greater power and torque. They also achieve improved fuel economy and emit fewer pollutants, especially carbon dioxide. GDI can also employ ‘stratified charge’ combustion. This technique forms a richer fuel mixture near the spark plug to ensure better ignition, while the remaining area of the chamber holds a leaner mix. As a result, both performance and efficiency can be enhanced.

However, GDI systems bring their own set of challenges. They are generally costlier and complicated compared to MPFI systems. One common issue is carbon build-up on the intake valves, since fuel does not pass over them as it does in MPFI setups. As a result, maintenance and servicing can be more expensive. Moreover, the system relies on high-quality fuel to perform at its best.

GDI work best alongside turbocharged engines. This pairing enables smaller engines to produce high power while remaining fuel-efficient. In some cases, manufacturers adopt a dual-injection system that incorporates both MPFI and GDI technologies. In such setups, one set of injectors delivers fuel into the intake port, while another injects it straight into the combustion chamber — best of both worlds.

A Milestone in Automotive Engineering

Although MPFI has been a reliable system in the automotive industry for many years, newer technologies such as Gasoline Direct Injection are slowly replacing it as manufacturers seek improved efficiency and performance. GDI systems provide more accurate fuel control and are more effective in meeting stringent emission standards, even though they tend to involve higher costs and greater maintenance requirements. A shift in focus towards EVs is also slowing down the R&D on both systems.

With ongoing advancements in automotive engineering, there is a clear shift towards smarter and more efficient fuel delivery systems. Regardless of whether it is MPFI or GDI, the primary objective remains unchanged, which is to deliver peak performance while reducing environmental impact and fuel consumption.

FAQs

1. How is MPFI better than a carburettor?

MPFI systems offer better fuel efficiency, engine performance, easier cold starts and lower emissions compared to carburettors. They improve mileage by optimising the air-fuel mixture for more efficient combustion.

2. Is MPFI good for long-term engine health?

Yes, MPFI systems ensure optimal fuel delivery across engine cylinders, thereby reducing engine wear and helping maintain long-term performance.

3. Are MPFI engines expensive to maintain?

Although generally reliable, they can be slightly more expensive to repair due to the use of sophisticated sensors and electronic components.

4. How often should MPFI injectors be cleaned?

Injector cleaning is typically recommended every 20,000 to 30,000 kilometres, depending on fuel quality and driving habits.

5. Is MPFI used in both petrol and diesel cars?

MPFI is mainly used in petrol engines. Diesel engines use a different type of fuel injection system, such as Common Rail Direct Injection.